Mohler. India

Mohler is a leading manufacturer and exporter of Overhead Travelling Cleaners, prioritizing quality and customer service. As a CE-certified company, they utilize advanced technologies to produce high-performance cleaners for the spinning, weaving, and processing industries. Explore more http://www.mohlermachine.com/

Products:

Mohler. India

Yarn Conditioning

Mohler’s presence in India’s textile sector is strongly marked by its advanced Yarn Conditioning Plants. These systems, designed with a focus on enhancing yarn quality, address critical needs within the Indian textile industry. Mohler’s technology, which emphasizes features like precise moisture control and contamination-free processing, is particularly relevant in a market where high-quality yarn is essential for competitive textile production.

- VARIETY OF YARNS

- Cotton Waxed

- Dyed Yarn

- Cotton Unwaxed

- Polyester Cotton

- Polyester Viscose

- Melange Yarn

- Industrial Yarn

- Polyester Wool/Worsted

- Lycra Blends

Transportation system

Mohler Machine Works, with a strong presence in India, offers advanced Bobbin Transport Systems (BTS) designed to optimize material flow within textile spinning mills. These systems, utilizing German technology, streamline the movement of bobbins, reducing manual handling and increasing efficiency.

Overhead cleaners

Mohler Machine Works, based in Coimbatore, India, has established itself as a leading manufacturer and exporter of Overhead Travelling Cleaners (OHTCs) within the Indian textile industry. Recognizing the critical need for maintaining clean environments in spinning, weaving, and processing facilities, Mohler provides a range of OHTC solutions tailored to diverse operational requirements.

- Belt Driven Model

- Power Duct Bus Bar Model

- Chain Link Model

- OHTC For Looms

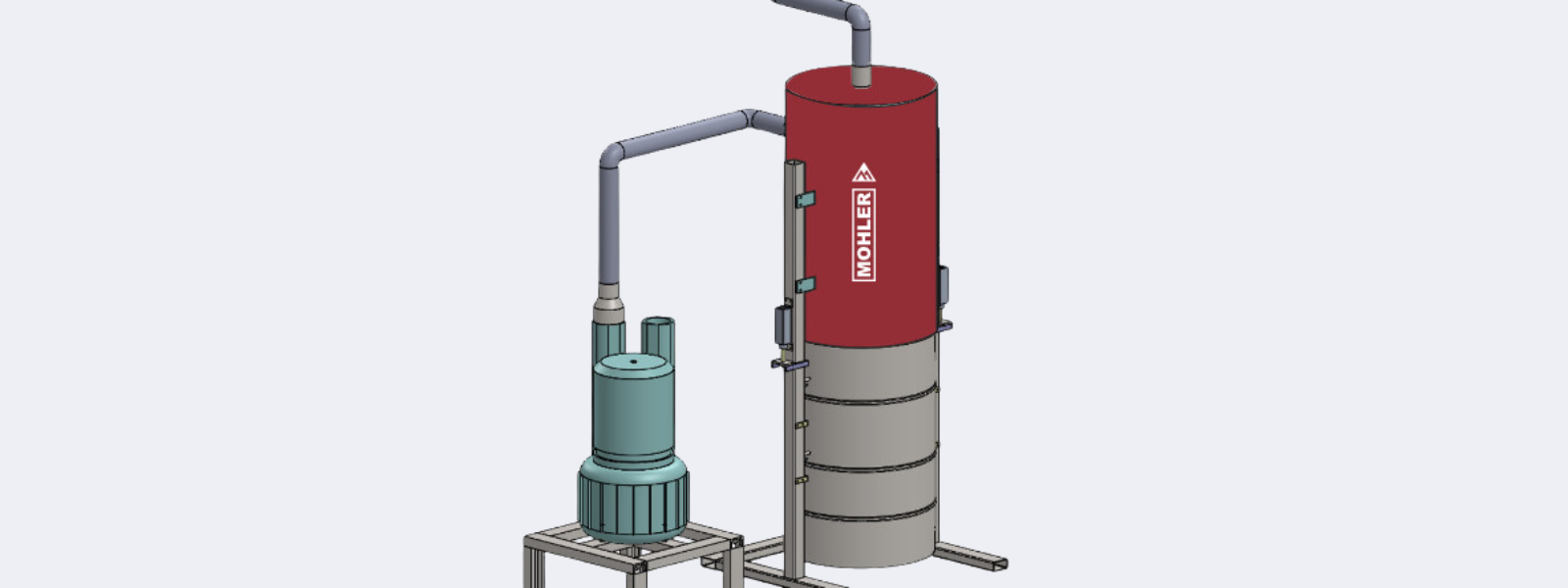

Central Vacum Cleaning System

The Mohler CENVAC central vacuum cleaning system presents a single-point,

centralized solution designed primarily for spinning and weaving mills.

It’s positioned as a “fit and forget” system, emphasizing its low maintenance requirements.

This approach contrasts sharply with traditional cleaning methods that necessitate dragging equipment across the factory floor,

a process that can lead to cable damage, electrical hazards from short circuits, and general wear and tear.

The CENVAC system aims to mitigate these issues,

offering a streamlined cleaning process that ultimately saves both time and labor,

both of which are critical considerations within the fast-paced environment of textile mills.