MOKSHA. India

Moksha, a family concern with over 60 years of experience and a third generation boasting plastics and engineering backgrounds, is dedicated to continuous innovation and customer satisfaction. Operating a modern 70,000 sq. ft. injection moulding plant near Ahmedabad. Explore More about http://www.mokshabobbins.com/

Products:

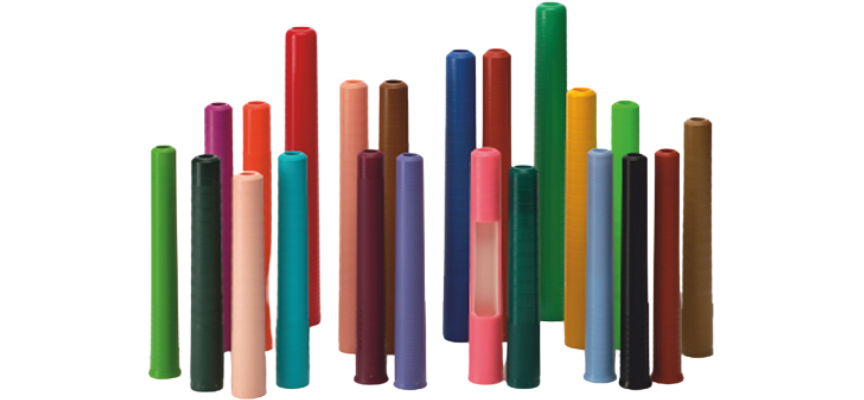

Spinning tubes

Slim-Line Ring Spinning Tubes

- Engineered upto 1.5mm thickness from Various ‘Moksha’ Proprietary Polymer alloys Maintain Superlative Rigidity and Resist compression by Hoop Stress of wound yarns. With Dimensional Stability at High Spinning speeds & having exceptional doffing capabilities Remarkable gains in

- Productivity / Noticeable impact on the U/Kg.

- Designed for Auto-doffer, Retrofit and Manual doffing with Linked/Non Linked winding systems.

Ring Spinning Frame & Doubling Tubes

- Superior Precision Ring Frame tubes for Auto-doffing machines for Speeds upto 25000 and for all Ring Frames with Manual/Retrofitted Doffing Systems

- Posiloc Tubes – Patent applied – Harmonized for Centrifugal Clutch Spindles of LMW.

Roving bobbins

Speed Frame Bobbins

Moksha’s High Precision ABS Simplex Bobbins are designed to optimize performance across all machine makes, specifically catering to auto-doffing and BTS (Bobbin Transport System) requirements. Constructed from durable ABS, these bobbins offer exceptional dimensional accuracy and stability, crucial for consistent roving delivery. To further enhance operational efficiency, Moksha provides Colour Identification Rings, enabling precise yarn segregation and minimizing the risk of mixing different yarn types.

- High Precision ABS Simplex Bobbins for all makes of machines: Auto-doffing & BTS.

- Colour Identification Rings for Additional Yarn Segregation

- Hook Rings for Full/Partial Creel change Auto-doffing enabled BTS systems, preventing roving wastage.

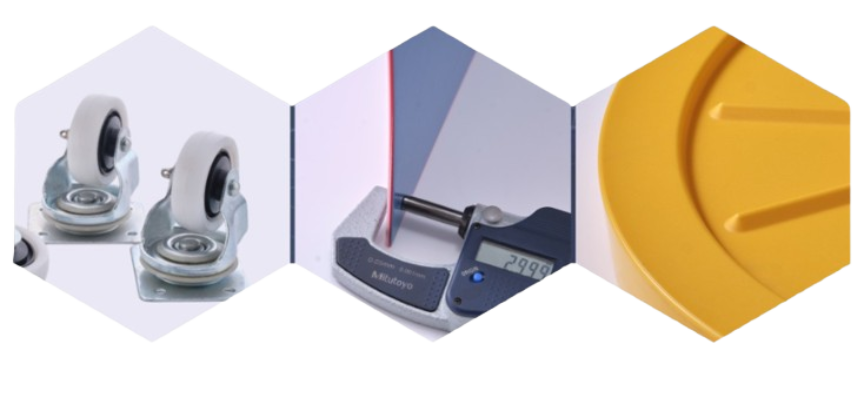

Cans & Gastors

- CNC-Made High Tensile Alloyed Springs with Precise Control on Balance Motion Post Processed on State-of-The-Art Hardening and Tempering Equipment to Ensure a Long-Active Spring Coil- Recoil with the Highest Repeatability Performance Fatigue Value and Elasticity Retention of the Springs

- For Gentle Sliver Handling Customised Spring Load Designed For: Carding, Draw Frames, Comber, Breaker & Finisher Draw Frames, O/E & Vortex Spinning

- Anti-Static ABS/ PP Alloys Top-Plates-Created with Innovative Surface & Effective

- Anti-Slip Surface

- Precision Flat Moulded

- Without Stress on the Sliver & Eliminate Fibre Migration caused by Sliver Layer Remnants

- Stainless Steel Top Rings with Highly Polished Surface and Binders in Concealed Joint for Excellent Sliver Handling and Preventing Imperfections

- 100% Virgin Quality Polymer Alloy Can Body from Proprietary “Trio” Sheet with ‘X’ Linked Central Layer

- Excellent Anti-Static Property High Strength Seamless Joint of

the Cylindrical Body - Elongates Life Cycle, for Trouble

- Free Operations

- Sturdy Fluff Protected Castors Designed to Ensure Smooth Manipulation Within the Plant and an Excellent Trouble Free Life Cycle

- Sturdy Fluff Protected Castors Designed to Ensure Smooth Manipulation Within the Plant and an Excellent Trouble Free Life Cycle

- High Quality Tie-Ropes Tether the Top Plate with Provisions Made for on-the-go Alignment Adjustment for Lateral Positioning and Prevention of Sliver Fraying

Highlights of the Moksha 'Engineered' Sliver Cans

- Sturdy Fluff protected Castors designed to ensure smooth maneuvering within the plant and a higher life cycle.

- Available starting with 400, 445/450, 500, 600, 700, 800, 900, 1000 and 1200mm sizes. Lengths as per Machinery demands. Other sizes will be introduced in the product portfolio shortly.

- Precision Spring Tension calculation and Quality Check systems employed to ensure consistence in quality with the “Moksha” Quality Assurance and Innovative Design Engine.

- High quality Tie-ropes tether the top plate with provisions made for on-the- go alignment adjustment as demanded.

- Assembly designed for Strict compliance with dimensional demands of OEM Machinery.

- Stainless Steel Top Rings with Highly Polished surface and Binders for excellent sliver handling and prevent imperfections.

- 100% Virgin quality Polymer alloy Can body from Proprietory “Trio” sheet: Excellent Anti-Static property, Centre Layer provides highest strength with Seamless joint of the Cylindrical Body-Elongates life cycle, for Trouble-free Operation & Coloured Anti Scratch Layer outside

- CNC-made Springs with precise control on Balance motion made on State-of-the-Art Hardening and Tempering Equipment to ensure a long-active spring coil-recoil with the highest repeatability standards for use of Sliver on Carding, Draw Frames, Comber, Finisher Draw Frames, Roving, Open End & Vortex Spinning.

- New Innovative surface design ABS/ PP Top-plates – Precision Flat moulded and creating the most effective Anti-slip surface without stressing the sliver with Anti- Static to eliminates fibre migration caused by sliver layer remnants.

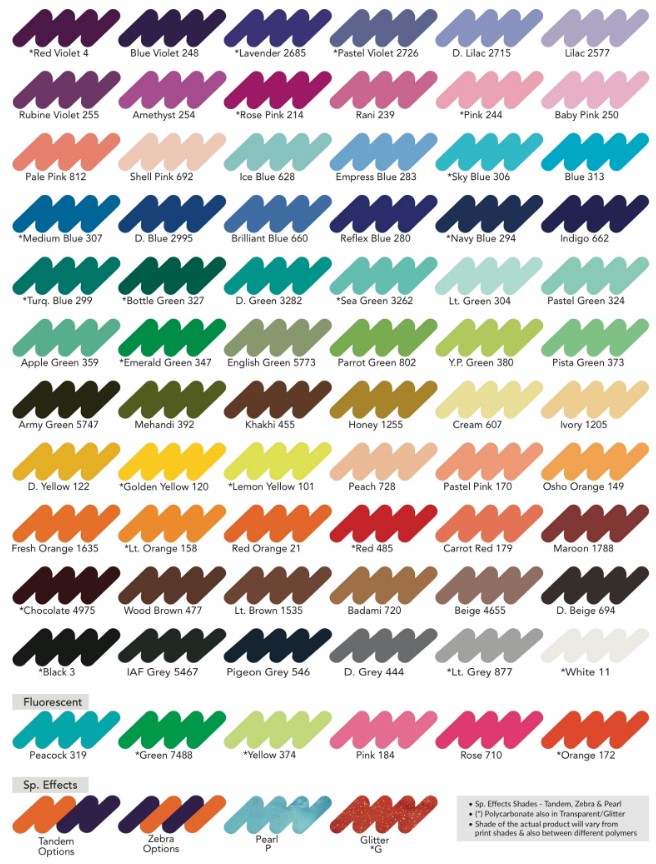

Moksha Palette

Moksha’s Palette offers a comprehensive and vibrant spectrum of colors, designed to provide a clear and effective visual identity for your yarns.

This extensive color range allows for precise yarn segregation and easy identification throughout the spinning process,

minimizing errors and maximizing efficiency.

Whether you require subtle distinctions for different yarn counts or bold colors for quick recognition,

Moksha’s palette provides the flexibility needed to streamline your operations and maintain quality control.

By incorporating these color-coded solutions, spinning mills can enhance their organizational systems and ensure accurate tracking of materials,

ultimately contributing to a more productive and error-free environment.